Among the many underground horizontal development methods, Drift Drilling and Blasting is a popular technique used in the mining industry. This process is used in the development stage of underground mining for the development of perimeter drifts, crosscuts, or ramps. It can also be used in the operation phase, where drift faces are blasted to advance in the orebody. The process of horizontal development requires a high level of consideration in drilling cuts, deviation, choosing the right drill bits, rock support, blasting delays and cost. Failing to have a proper design might incur heavy costs and long schedule delays due to the complication of the use of this method.

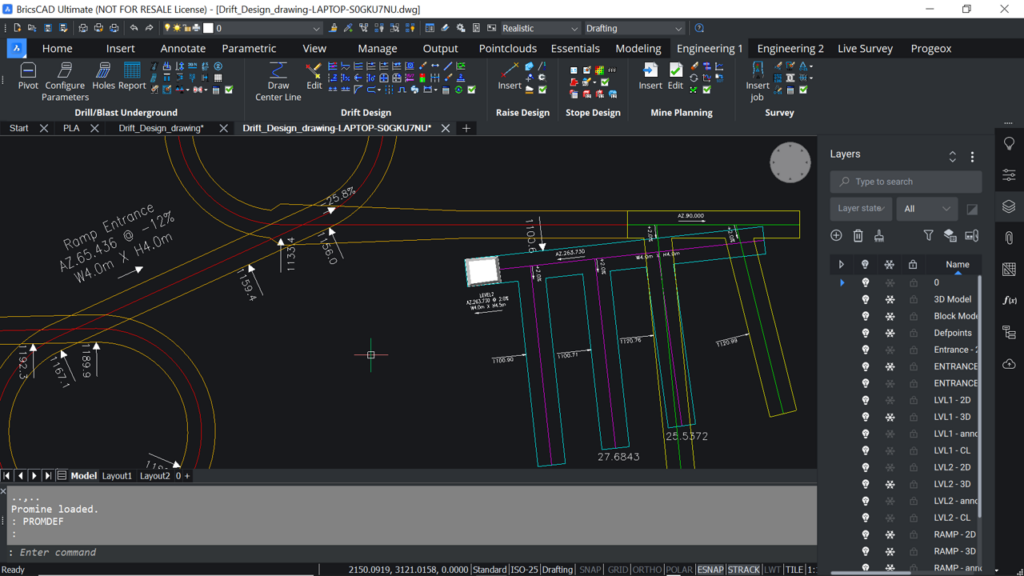

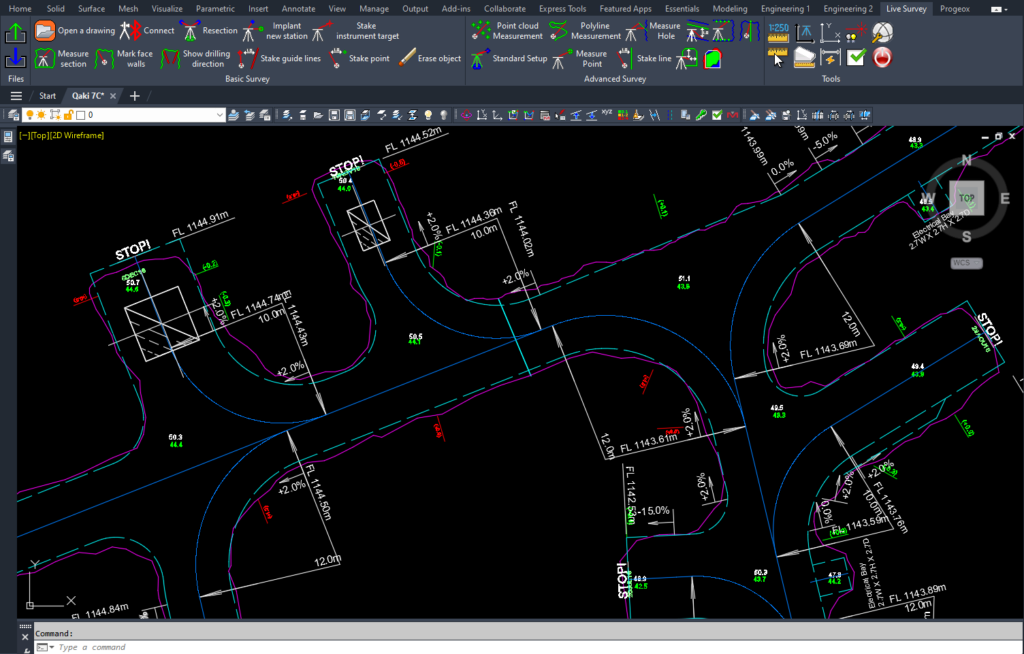

Drift Drilling and Blasting starts by drawing a pattern on a drift face in hard rock mining. This step is performed by a surveyor, where painting is used to identify the correct pattern. Following, drilling cuts and drill holes are then inserted on the face of the drift, in which a driller usually uses mechanical equipment to accomplish this step.

Once the drill holes are completed, a primer is used inside each hole to initiate the blast. Different types of explosives, packaged or in bulk, can then be used to charge the drilled holes. The explosives must contain enough pressure to break the rock, which creates a zone of crushed rock around each hole. A blast wave then occurs, which breaks the surrounding rock, resulting in crushed rock that could be easily mucked out. Furthermore, delays in blasting are used for efficient blasting. The actual delay between each detonation varies in milliseconds, which makes a huge difference in the final powder factor value.

Completing the full design of Drift Drilling and Blasting requires attention to detail. Each mine has a different RQD, thus, a series of trial and error is required before obtaining the optimal design. Having a software easy-to-use that allows you to quickly change your design is crucial to spend as less time as possible designing. Promine’s new module “Drift Drilling and Blasting” is a versatile and easy-to-use module that allows you to design drilling cuts, drill-and-blast holes, set delays and generate detailed reports to obtain a well-designed horizontal development. Using one of Promine’s core feature, you can collaborate with multiple users on the same design, facilitating the process between surveyors and drillers. Consequently, your operation team saves time and becomes more efficient.

For more information about the Drift Drilling and Blasting module and to contact a sales representative, click here.